Manufacturing processes and expertise

At VF Engineering, we offer you not only a wide range of manufacturing processes but also technical expertise and in-depth skills to meet all your industrial needs. Whether it's for small batches, prototypes, or mass production, our network of partners and our know-how ensure optimal quality at every stage. Below, discover an overview of the processes and competencies we master to bring your ideas to life..

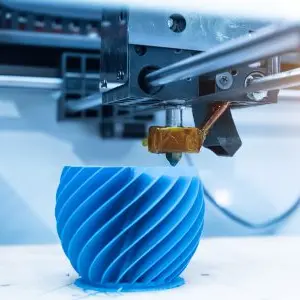

3D Printing and vacuum casting

SLA, SLS, SLM, MJF, and FDM technologies for the rapid creation of prototypes and small batches using various materials such as PA, aluminum, and steel. Vacuum casting allows for small batch productions with high-quality finishes..

Injection, extrusion, and molding

Includes plastic injection, extrusion, pressure molding, rotational molding, and die casting processes for producing parts in plastic, metal, and rubber (ABS, PE, PP, aluminum), suitable for both small and large batches.

Mechanical machining and electrical discharge machining

Precision machining via CNC, turning, milling, and electrical discharge machining. With various materials such as metal, wood, and plastic. We offer solutions for manufacturing parts requiring tight tolerances or, conversely, low costs.

Design of special machines and space mechanisms

In collaboration with Lemtronic and The Countdown Company, we design custom machines and offer enhancements (retrofits, protections). We also conduct spatial studies and analyses for optimized technical solutions.

Custom packaging

Creation of custom packaging in cardboard, wood, or plastic, including specific inserts to ensure the protection, transport, and optimal presentation of your products.

Wiring, connectors, and electromechanics

Customization of wiring (USB, ethernet, power), connectors, and electromechanical components such as motors and buttons for reliable solutions tailored to industrial needs.

Sheet metal, stamping, and surface treatment

Laser cutting, stamping, water jet cutting, and welding for the manufacturing of metal parts, combined with surface treatments such as anodizing, galvanizing, and PVD coatings to enhance the durability and aesthetics of the products.

Assembly, welding, and riveting

Optimization of assembly lines, integration of robotic welding, and assembly by riveting or bonding for metal and composite materials in large batches.

Product customization

Customization of standard products with engraving, silk screening, or other finishes to reflect the visual identity of your company or product range, regardless of the type of product.

Cabinetmaking and carpentry

CNC machining, turning, and other precision techniques applied to all types of wood (MDF, HDF, OSB, PVC, PB) for custom fitting and manufacturing projects in wood.

Batteries

Manufacturing of custom batteries (Li-ion, Li-Po, Lead-Acid) with customization options such as silk screening for perfect integration into your products.

Product certification

This list is not exhaustive, as we are constantly seeking new suppliers and partners to expand our offerings. We continually challenge our suppliers to ensure our clients receive the best quality at the best price.

This list is not exhaustive, as we are constantly seeking new suppliers and partners to expand our offerings. We continually challenge our suppliers to ensure our clients receive the best quality at the best price.