BIPED: An intelligent co-pilot for the visually impaired

Biped develops innovative solutions for visually impaired individuals, with a flagship product: the NOA, an intelligent harness equipped with cameras and AI. It acts as a co-pilot, assisting users in detecting obstacles, locating objects, and providing descriptions of their surroundings.

#Electronic #Overmolding #Battery #IntelRealSense #3DPrinting #R&D #Medical #Certification #AI #ImageProcessing #MachineLearning

The meeting

In 2022, Biped had a functional prototype, but the product still needed adjustments to meet market requirements. The team had strong expertise in artificial intelligence and image processing, aiming to create an autonomous assistant tailored to the specific needs of users. However, they lacked any hardware skills in-house.

The challenge

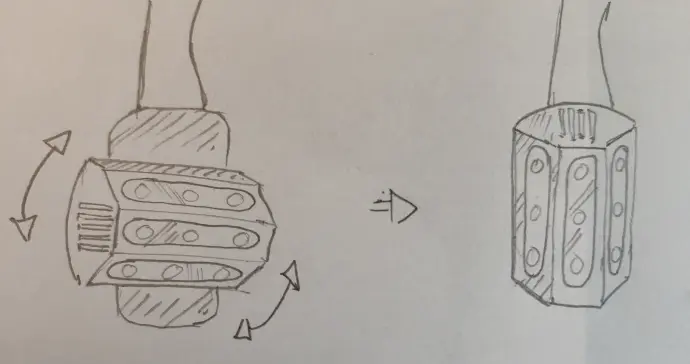

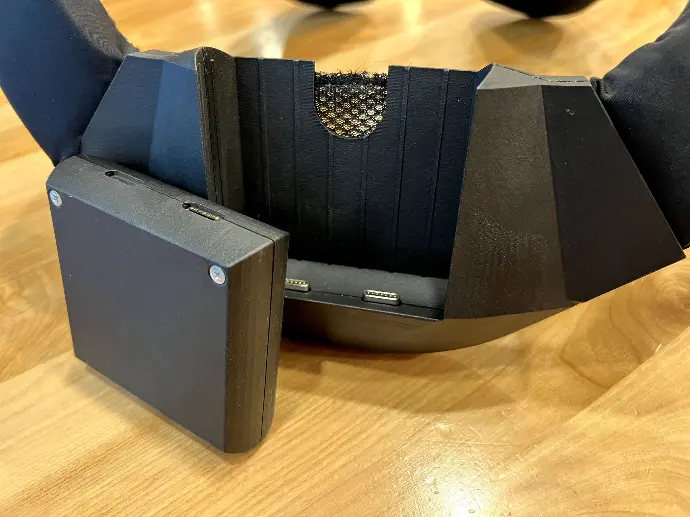

Our mission: to industrialize the product from this prototype while continuously adjusting the features based on user feedback. The absence of a fixed specifications document made this process adaptable. We produced small test batches to validate ergonomics and technical aspects.

The industrialization

We handled the hardware design (mechanical and electronic design), while Biped focused on software development. This collaboration allowed for rapid and regular iterations. At the same time, we developed MVPs of other products that reused the same technological foundation as the NOA, enabling Biped to explore new markets and establish partnerships.

Certifying the product as a medical device was another key aspect of the project. We worked closely with our certification partner to ensure that every component, every technical choice, and the final design complied with current regulatory standards.

The results

Two years later, Biped is in the production validation phase (PVT) with batches of 25 to 50 units, and an assembly line is being set up.

Thanks to an agile approach, the company has raised funds, established partnerships with leaders such as Honda Research Institute and P&G, and is already exporting its product worldwide.

"What convinced me about VF was the ability to develop a product without a fixed specifications document and to pivot"